ANTICHEM EQUIPMENTS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ANTICHEM EQUIPMENTS

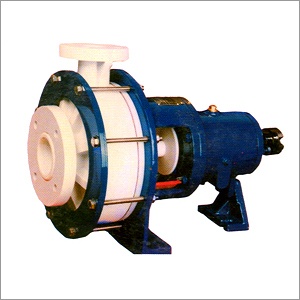

Centrifugal Chemical Process Pumps (Type Scp)

58193.jpg)

Constructional Features

Top centerline discharge, self-venting casing arranged for back pull-out. Fully confined gasket. Foot support under casing for maximum resistance of misalignment and distortion from pipe loads .

ANSI-B-16.5 (Class 150) flanges standard, ANSI-B16.5 (Class 300) optional for working pressure to 2550 kpa with 3mm corrosion allowance.

For maximum corrosion , erosion resistance casting is supplied without tapped openings but gauge and drain plug openings are provided when specified.

Impeller matched to casing for high efficiency and low NPSH. Fully open, has partial shrouds for maximum vane support without high thrust iherent in closed impellers.

Stuffing box pressure reduced and entrance of solid prevented by back pump-out vanes. Large smoothly contoured flow passages combine best slurry and solid handling ability.

Impeller is locked on shaft with impeller lock-nut and are sealed by PTFE gasket. State of the art casting methods smoothest possible surfaces for highest efficiency.

All impellers are statically and dynamically balanced.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

58193.jpg)

58194.jpg)